| Non-asbestos group(non-steel ~ low steel) |

|

|

|

|

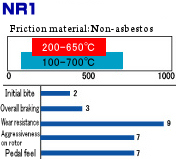

| NR1(bench-graph) |

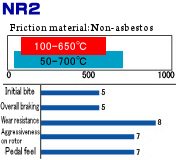

NR2(bench-graph) |

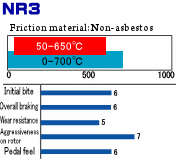

NR3(bench-graph) |

No data |

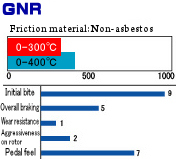

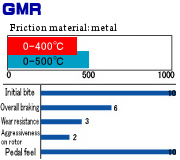

| Rear anti-lock friction material |

Rear control standard friction material |

Standard friction material for rear wheel drive

vehicles |

Rear friction material for side lock |

| Carbon group(low steel ~ high steel) |

|

|

|

|

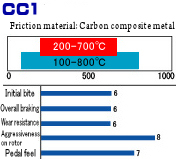

| CC1(bench-graph) |

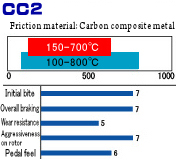

CC2(bench-graph) |

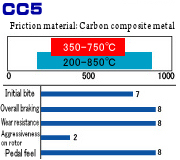

CC5(bench-graph) |

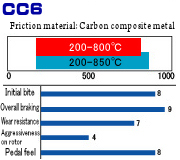

CC6(bench-graph) |

| Prioritizing controllability, racing use |

Prioritizing controllability, racing use |

Prioritizing high temperature high braking force ,

racing use |

Prioritizing high temperature high braking force ,

racing use |

| For the use at the high temperature by the circuit run, I give prevention

of detachment processing. |

| Semi-metallic group(middle steel ~ high steel) |

|

|

|

|

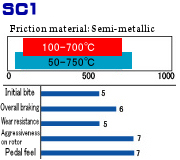

| SC1(bench-graph) |

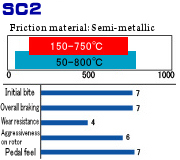

SC2(bench-graph) |

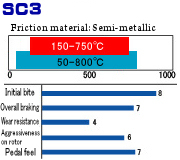

SC3(bench-graph) |

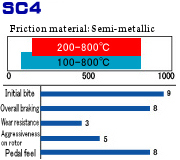

SC4(bench-graph) |

| Light weight vehicles, sprint racing use |

Light weight vehicles, sprint racing use |

Light weight vehicles, sprint racing use |

Light weight vehicles, sprint racing use |

|

|

No image |

No image |

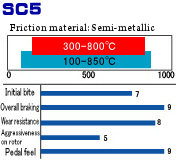

| SC5(bench-graph) |

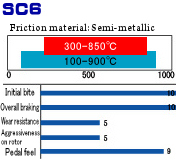

SC6(bench-graph) |

No data |

No data |

| Prioritizing controllability, high temperature

racing use |

Prioritizing braking force, high temperature racing

use |

No data |

No data |

| For the use at the high temperature by the circuit run, I give prevention

of detachment processing. |

| Durable metal group(high metal ~

full metal) |

|

|

|

|

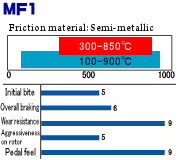

| MF1(bench-graph) |

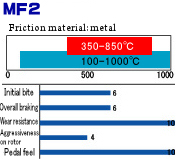

MF2(bench-graph) |

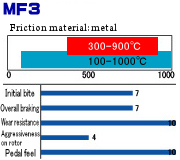

MF3(bench-graph) |

No data |

| Prioritizing high temperature stability, endurance

racing use |

Prioritizing high temperature stability, endurance

racing use |

Prioritizing high temperature stability, endurance

racing use |

Rear friction material for side lock |

| For the use at the high temperature by the circuit run, I give prevention

of detachment processing. |